Glass is a unique and extremely versatile material that can be engineered to exhibit specific optical, thermal, chemical, and mechanical properties. As a result of its exceptional engineering properties – transparency, strength, workability, transmittance and u value, glass has been heavily used in the construction industry. We will briefly feature some of the most common commercial glass types and typical applications.

Annealed Glass

Annealed glass is the basic float or flat glass that hasn’t been heat-strengthened or tempered and it tends to break into large, jagged shards. It is used in some end products and often in double-glazed windows.

Heat Strengthen Glass

With heat-strengthened glass, the cooling process is slower, which results in lower compression strength. Heat-strengthened glass is approximately twice as strong as annealed, or untreated, glass.

Fully Tempered Glass

Before the glass can be used as a building material it is often heat-treated for durability and safety. There are two different types of heat-treated glasses, heat-strengthened and tempered. While the production process is similar, heating the glass to approximately 1.200 degrees Fahrenheit and then force-cooling, the cooling process in tempered glass is accelerated to create a higher surface and/or edge compression in the glass. This process makes the glass four to five times stronger and safer than annealed or untreated glass. Fully-tempered safety glass is often used for other applications where safety is desirable, because of its break pattern or when significant additional strength is needed to resist wind pressure, thermal stress or both.

Laminated Glass

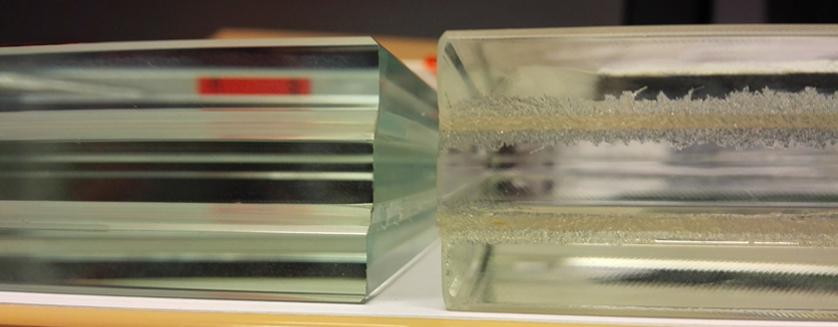

Laminated glass or laminated safety glass is made of two or more layers of glass with one or more "interlayers" of polymeric material bonded between the glass layers. Depending on the production method, laminated glass is classified in the below categories:

Poly Vinyl Butyral or

PVB laminated glass is produced using heat and pressure to sandwich a thin layer of PVB between layers of glass.

SGP stands for

SentryGuard Plus Interlayer manufactured by Dupont. Thanks to its high-security performance, the SGP can withstand severe weather conditions such as storms, hurricane, and cyclones. The SGP also demonstrates higher post breakage strength, as the interlayer offers five times the tear strength and 100 times the rigidity of the more conventional PVB interlayer. Another common polymer known as

Ethyl Vinyl Acetate (EVA) is frequently combined with other materials to achieve striking decorative effects.An alternative laminating technique to standard interlayer lamination using PVB or Sentry interlayers is

Resin Lamination or

Cast in Place (CIP). Resin lamination involves mechanically holding two panels of glass together and pouring liquid resin into the small gap in-between. Once the small cavity between the glass panels has been filled, the resin is then cured, either using a chemical process or under the effect of ultraviolet radiation on UV beds. Resin lamination is especially suited to glass panels with an uneven surface such as kiln formed or cast glass.Laminated glass is used extensively in building and housing products and in the automotive and transport industries vastly on account of its advanced safety features. Laminated glass displays high-performance impact and bullet resistance capabilities as well as fragment retention performance. So, instead of shattering on impact, it is held together by the interlayer which reduces the safety hazard from the shattered glass fragments. But the interlayer also provides a way to apply several other technologies and benefits, such as coloring, sound dampening, resistance to fire, ultraviolet filtering and other technologies that can be embedded in or with the interlayer.

Insulated Glass

Insulated glass consists of two or more plies of glass separated by an aluminum or other types of spacer and is filled with air or in some cases noble gases like argon to influence the element’s Ug value. The combination of two panels of glasses and the trapped air is what makes insulated glass a superior energy efficient method of glazing. Inherently, insulated glass demonstrates high thermal performance by reducing heat gain in summers and heat loss and condensation in winters. Among other benefits, the use of insulated glass can contribute to lowering cooling and heating costs, UV transmission, while maintaining wind load strength.

Low-iron/ Extra Clear Glass

Low-iron/ Extra Clear Glass

Extra clear glass is created by reducing the amount of iron within its content which removes the green tint inherent in standard glass. Extra clear glass’s almost completely transparent appearance means it has limited sun reflection properties. It is particularly useful in solar energy applications where it is important that the glass cover lets light through to reach the thermal tubes or photovoltaic cells. Anti-reflective properties can be further increased by applying a special coating on the low-iron glass. It’s widely used in windows or facades as it offers brilliant clarity, which allows occupants to appreciate true colours and to enjoy true-to-life views.

Coated

Surface coatings can be applied to glass to modify its appearance and influence or improve its properties, such as low maintenance, special reflection/transmission/absorption properties, scratch resistance, corrosion resistance, etc. Coatings are usually applied by controlled exposure of the glass surface to vapours, which bind to the glass, forming a permanent coating. The coating process can be applied while the glass is still in the float line with the glass still warm, producing what is known as "hard-coated" glass. Alternatively, in the "off-line" or "vacuum" coating process, the vapour is applied to the cold glass surface in a vacuum vessel.

Decorative Glass

Today, there are various decorative glass types offer a variety of design options for residential or commercial solutions.

Acid etched is called the glass that has been chemically treated with an acidic material, such as hydrofluoric acid, to produce a surface finish that will diffuse transmitted light, reduce glare and has a “frosted” appearance. The treatment on the glass is used to diffuse light, reduce glare and obtain a translucent appearance. The treatment on a mirror is used to obtain a soft matted reflection. The treatment can be applied to provide different levels of translucence, either uniformly over the entire surface or in selected areas creating decorative patterns.

While a

Ceramic Frit or

Silk Screen is a pigmented glass enamel fired onto the glass at temperatures in excess of 1,200 degrees Fahrenheit and permanently fused to the glass surface. Ceramic frit can be applied using a full coverage coating process, a silk screen process or a pre-printed ceramic decal. This type of decorative glass is available in many colors, patterns, and translucencies and is used for both exterior and interior applications.

Glass is a unique and extremely versatile material that can be engineered to exhibit specific optical, thermal, chemical, and mechanical properties. As a result of its exceptional engineering properties – transparency, strength, workability, transmittance and u value, glass has been heavily used in the construction industry. We will briefly feature some of the most common commercial glass types and typical applications.Annealed Glass

Annealed glass is the basic float or flat glass that hasn’t been heat-strengthened or tempered and it tends to break into large, jagged shards. It is used in some end products and often in double-glazed windows.Heat Strengthen Glass

With heat-strengthened glass, the cooling process is slower, which results in lower compression strength. Heat-strengthened glass is approximately twice as strong as annealed, or untreated, glass.Fully Tempered Glass

Before the glass can be used as a building material it is often heat-treated for durability and safety. There are two different types of heat-treated glasses, heat-strengthened and tempered. While the production process is similar, heating the glass to approximately 1.200 degrees Fahrenheit and then force-cooling, the cooling process in tempered glass is accelerated to create a higher surface and/or edge compression in the glass. This process makes the glass four to five times stronger and safer than annealed or untreated glass. Fully-tempered safety glass is often used for other applications where safety is desirable, because of its break pattern or when significant additional strength is needed to resist wind pressure, thermal stress or both.Laminated Glass

Laminated glass or laminated safety glass is made of two or more layers of glass with one or more "interlayers" of polymeric material bonded between the glass layers. Depending on the production method, laminated glass is classified in the below categories:Poly Vinyl Butyral or PVB laminated glass is produced using heat and pressure to sandwich a thin layer of PVB between layers of glass. SGP stands for SentryGuard Plus Interlayer manufactured by Dupont. Thanks to its high-security performance, the SGP can withstand severe weather conditions such as storms, hurricane, and cyclones. The SGP also demonstrates higher post breakage strength, as the interlayer offers five times the tear strength and 100 times the rigidity of the more conventional PVB interlayer. Another common polymer known as Ethyl Vinyl Acetate (EVA) is frequently combined with other materials to achieve striking decorative effects.An alternative laminating technique to standard interlayer lamination using PVB or Sentry interlayers is Resin Lamination or Cast in Place (CIP). Resin lamination involves mechanically holding two panels of glass together and pouring liquid resin into the small gap in-between. Once the small cavity between the glass panels has been filled, the resin is then cured, either using a chemical process or under the effect of ultraviolet radiation on UV beds. Resin lamination is especially suited to glass panels with an uneven surface such as kiln formed or cast glass.Laminated glass is used extensively in building and housing products and in the automotive and transport industries vastly on account of its advanced safety features. Laminated glass displays high-performance impact and bullet resistance capabilities as well as fragment retention performance. So, instead of shattering on impact, it is held together by the interlayer which reduces the safety hazard from the shattered glass fragments. But the interlayer also provides a way to apply several other technologies and benefits, such as coloring, sound dampening, resistance to fire, ultraviolet filtering and other technologies that can be embedded in or with the interlayer.Insulated Glass

Insulated glass consists of two or more plies of glass separated by an aluminum or other types of spacer and is filled with air or in some cases noble gases like argon to influence the element’s Ug value. The combination of two panels of glasses and the trapped air is what makes insulated glass a superior energy efficient method of glazing. Inherently, insulated glass demonstrates high thermal performance by reducing heat gain in summers and heat loss and condensation in winters. Among other benefits, the use of insulated glass can contribute to lowering cooling and heating costs, UV transmission, while maintaining wind load strength.

Glass is a unique and extremely versatile material that can be engineered to exhibit specific optical, thermal, chemical, and mechanical properties. As a result of its exceptional engineering properties – transparency, strength, workability, transmittance and u value, glass has been heavily used in the construction industry. We will briefly feature some of the most common commercial glass types and typical applications.Annealed Glass

Annealed glass is the basic float or flat glass that hasn’t been heat-strengthened or tempered and it tends to break into large, jagged shards. It is used in some end products and often in double-glazed windows.Heat Strengthen Glass

With heat-strengthened glass, the cooling process is slower, which results in lower compression strength. Heat-strengthened glass is approximately twice as strong as annealed, or untreated, glass.Fully Tempered Glass

Before the glass can be used as a building material it is often heat-treated for durability and safety. There are two different types of heat-treated glasses, heat-strengthened and tempered. While the production process is similar, heating the glass to approximately 1.200 degrees Fahrenheit and then force-cooling, the cooling process in tempered glass is accelerated to create a higher surface and/or edge compression in the glass. This process makes the glass four to five times stronger and safer than annealed or untreated glass. Fully-tempered safety glass is often used for other applications where safety is desirable, because of its break pattern or when significant additional strength is needed to resist wind pressure, thermal stress or both.Laminated Glass

Laminated glass or laminated safety glass is made of two or more layers of glass with one or more "interlayers" of polymeric material bonded between the glass layers. Depending on the production method, laminated glass is classified in the below categories:Poly Vinyl Butyral or PVB laminated glass is produced using heat and pressure to sandwich a thin layer of PVB between layers of glass. SGP stands for SentryGuard Plus Interlayer manufactured by Dupont. Thanks to its high-security performance, the SGP can withstand severe weather conditions such as storms, hurricane, and cyclones. The SGP also demonstrates higher post breakage strength, as the interlayer offers five times the tear strength and 100 times the rigidity of the more conventional PVB interlayer. Another common polymer known as Ethyl Vinyl Acetate (EVA) is frequently combined with other materials to achieve striking decorative effects.An alternative laminating technique to standard interlayer lamination using PVB or Sentry interlayers is Resin Lamination or Cast in Place (CIP). Resin lamination involves mechanically holding two panels of glass together and pouring liquid resin into the small gap in-between. Once the small cavity between the glass panels has been filled, the resin is then cured, either using a chemical process or under the effect of ultraviolet radiation on UV beds. Resin lamination is especially suited to glass panels with an uneven surface such as kiln formed or cast glass.Laminated glass is used extensively in building and housing products and in the automotive and transport industries vastly on account of its advanced safety features. Laminated glass displays high-performance impact and bullet resistance capabilities as well as fragment retention performance. So, instead of shattering on impact, it is held together by the interlayer which reduces the safety hazard from the shattered glass fragments. But the interlayer also provides a way to apply several other technologies and benefits, such as coloring, sound dampening, resistance to fire, ultraviolet filtering and other technologies that can be embedded in or with the interlayer.Insulated Glass

Insulated glass consists of two or more plies of glass separated by an aluminum or other types of spacer and is filled with air or in some cases noble gases like argon to influence the element’s Ug value. The combination of two panels of glasses and the trapped air is what makes insulated glass a superior energy efficient method of glazing. Inherently, insulated glass demonstrates high thermal performance by reducing heat gain in summers and heat loss and condensation in winters. Among other benefits, the use of insulated glass can contribute to lowering cooling and heating costs, UV transmission, while maintaining wind load strength. Low-iron/ Extra Clear Glass

Extra clear glass is created by reducing the amount of iron within its content which removes the green tint inherent in standard glass. Extra clear glass’s almost completely transparent appearance means it has limited sun reflection properties. It is particularly useful in solar energy applications where it is important that the glass cover lets light through to reach the thermal tubes or photovoltaic cells. Anti-reflective properties can be further increased by applying a special coating on the low-iron glass. It’s widely used in windows or facades as it offers brilliant clarity, which allows occupants to appreciate true colours and to enjoy true-to-life views.Coated

Surface coatings can be applied to glass to modify its appearance and influence or improve its properties, such as low maintenance, special reflection/transmission/absorption properties, scratch resistance, corrosion resistance, etc. Coatings are usually applied by controlled exposure of the glass surface to vapours, which bind to the glass, forming a permanent coating. The coating process can be applied while the glass is still in the float line with the glass still warm, producing what is known as "hard-coated" glass. Alternatively, in the "off-line" or "vacuum" coating process, the vapour is applied to the cold glass surface in a vacuum vessel.Decorative Glass

Today, there are various decorative glass types offer a variety of design options for residential or commercial solutions.Acid etched is called the glass that has been chemically treated with an acidic material, such as hydrofluoric acid, to produce a surface finish that will diffuse transmitted light, reduce glare and has a “frosted” appearance. The treatment on the glass is used to diffuse light, reduce glare and obtain a translucent appearance. The treatment on a mirror is used to obtain a soft matted reflection. The treatment can be applied to provide different levels of translucence, either uniformly over the entire surface or in selected areas creating decorative patterns.

Low-iron/ Extra Clear Glass

Extra clear glass is created by reducing the amount of iron within its content which removes the green tint inherent in standard glass. Extra clear glass’s almost completely transparent appearance means it has limited sun reflection properties. It is particularly useful in solar energy applications where it is important that the glass cover lets light through to reach the thermal tubes or photovoltaic cells. Anti-reflective properties can be further increased by applying a special coating on the low-iron glass. It’s widely used in windows or facades as it offers brilliant clarity, which allows occupants to appreciate true colours and to enjoy true-to-life views.Coated

Surface coatings can be applied to glass to modify its appearance and influence or improve its properties, such as low maintenance, special reflection/transmission/absorption properties, scratch resistance, corrosion resistance, etc. Coatings are usually applied by controlled exposure of the glass surface to vapours, which bind to the glass, forming a permanent coating. The coating process can be applied while the glass is still in the float line with the glass still warm, producing what is known as "hard-coated" glass. Alternatively, in the "off-line" or "vacuum" coating process, the vapour is applied to the cold glass surface in a vacuum vessel.Decorative Glass

Today, there are various decorative glass types offer a variety of design options for residential or commercial solutions.Acid etched is called the glass that has been chemically treated with an acidic material, such as hydrofluoric acid, to produce a surface finish that will diffuse transmitted light, reduce glare and has a “frosted” appearance. The treatment on the glass is used to diffuse light, reduce glare and obtain a translucent appearance. The treatment on a mirror is used to obtain a soft matted reflection. The treatment can be applied to provide different levels of translucence, either uniformly over the entire surface or in selected areas creating decorative patterns.  While a Ceramic Frit or Silk Screen is a pigmented glass enamel fired onto the glass at temperatures in excess of 1,200 degrees Fahrenheit and permanently fused to the glass surface. Ceramic frit can be applied using a full coverage coating process, a silk screen process or a pre-printed ceramic decal. This type of decorative glass is available in many colors, patterns, and translucencies and is used for both exterior and interior applications.

While a Ceramic Frit or Silk Screen is a pigmented glass enamel fired onto the glass at temperatures in excess of 1,200 degrees Fahrenheit and permanently fused to the glass surface. Ceramic frit can be applied using a full coverage coating process, a silk screen process or a pre-printed ceramic decal. This type of decorative glass is available in many colors, patterns, and translucencies and is used for both exterior and interior applications.